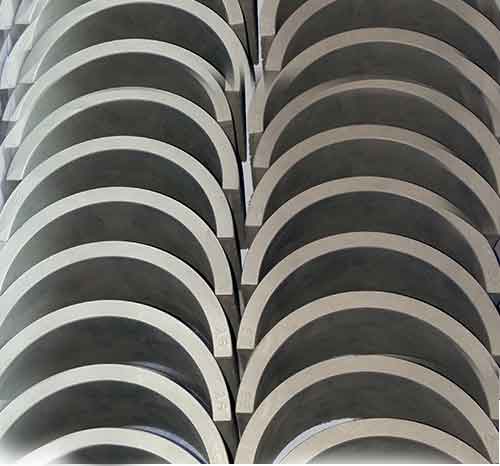

Super India Spares offers premium Stoker Bush bearings designed for extreme temperatures and demanding applications. These self-lubricating bearings ensure durability, efficiency, and reliability in industries like power plants, heavy manufacturing, and high-temperature processing. Built with advanced materials and precision engineering, they optimize machinery performance for long-lasting operation.

Self-Lubricating Mechanism

Stoker Bush bearings by Super India Spares utilize embedded solid lubricants within their carbon-graphite matrix. This eliminates dependency on external lubrication systems, even in environments exceeding 500°C, where traditional oils or greases would oxidize or evaporate.

Premium Carbon-Graphite Composition

Super India Spares manufactures Stoker Bush bearings using high-purity, isotropic carbon-graphite. This material offers:

Thermal Conductivity: Efficient heat dissipation to prevent localized overheating.

Oxidation Resistance: Stable performance in oxidizing atmospheres up to 450°C.

Compressive Strength: Withstands loads exceeding 50 MPa, ideal for heavy cyclic stresses.

Precision Customization

Super India Spares provides bespoke engineering solutions, tailoring Stoker Bush bearings to exact dimensions (tolerances within ±0.05 mm) for seamless integration with travel grates, boiler systems, and rotary equipment.

Low Coefficient of Friction (µ < 0.15)

The engineered graphite structure minimizes friction, reducing energy losses and wear on mating components.

Extended Service Life:

Stoker Bush bearings exhibit wear rates below 0.2 mm/1000 hours in abrasive environments, outperforming traditional bronze or babbitt bearings.

Thermal Shock Resistance:

With a thermal expansion coefficient of 4.5 × 10⁻⁶/°C, these bearings maintain dimensional stability during rapid temperature fluctuations.

Chemical Inertness:

Resistant to acids, alkalis, and steam, making them suitable for corrosive industrial processes.

ISO-Certified Manufacturing

Our state-of-the-art facility adheres to ISO 9001:2015 standards, ensuring consistent quality and traceability.

Technical Support and Customization

Super India Spares offers application-specific engineering support, including Finite Element Analysis (FEA) to optimize bearing geometry for your machinery.

Global Supply Chain Efficiency

With streamlined logistics, we ensure timely delivery of standardized or customized bearings to meet urgent operational needs.

Maximize uptime, reduce maintenance costs, and enhance operational efficiency with Stoker Bush bearings engineered for extreme industrial challenges. Super India Spares combines decades of tribological expertise with cutting-edge manufacturing to deliver solutions that outperform conventional bearings.

Engineered for extreme temperatures, our fiber bearings and silicon carbide seals ensure durability, reliability, and smooth operations in steel manufacturing.

Enhance efficiency and durability in paper manufacturing with our high-quality carbon sealing rings, rotary steam joints, and wear-resistant ceramic components.

Enhance efficiency and reliability in agricultural equipment with our wear-resistant carbon vanes and graphite components, ensuring long-lasting performance in tough conditions.

Engineered for high-pressure and high-temperature environments, our carbon sealing rings, rotary pressure joints, and thrust pads ensure durability and efficiency in oil rigs and refineries.

Durable carbon brushes, radial bearings, and metal bellows seals for efficient power generation. Designed for high-temperature, high-pressure environments to ensure reliability.

Leak-proof sealing solutions, including gland packing rings and bush bearings, for durable water treatment systems. Designed for desalination, wastewater, and fluid handling applications.

Engineered for durability and efficiency, our clutch bearings, carbon brushes, and seal rings enhance vehicle performance, ensuring smooth operation in fuel, cooling, and transmission systems.

Corrosion-resistant stoker bushes, thrust pads, and seal rings for efficient sugar production. Designed for durability, reliability, and minimal downtime in mill operations.

Food-grade sealing solutions for safe, efficient processing and packaging. Designed for durability, hygiene compliance, and reliable performance in food production.

+91-9324779103

+91-9867709103

+91-9769827066

B/103, Plot No. 15, Prathana Bldg., Jawahar Nagar, S.V. Road, Goregaon (W), Mumbai - 400062, Maharashtra, India.

info@superindiaspares.com

Copyright © 2025. All Rights Reserved. Site Developed by Integral Web Solution